International Headquarters in Brighouse, England, United Kingdom: Halifax Rack & Screw Cutting Company Ltd. (HRS) was formed in 1953 to manufacture and supply gear rack, pinions, lead screws, power nuts and associated hardware to the machine tool, power transmission and motion control industries. HRS is one of the world leaders in the dedicated supply of these kinds of parts. EELLC has been representing HRS in North America since 2007. HRS manufactures at the Brighouse location and manages all its business outside of North America from this facility. In the mid-1990’s HRS recognized the benefits to maintaining a local support organization in the US for their North American business. For additional information please visit www.halifaxrs.com

Precision Gear Racks

Precision gear racks have longer in service lives, smoother performance characteristics and more accurate pitch control than other machining techniques. HRS can machine in straight, spur and helical tooth forms up to 45 degrees, with a 450mm/17.75 inch face width and height and up to 12 meters/40 ft. long. HRS utilizes specially dedicated CNC rack cutting machines to ensure the highest accuracy up to AGMA class 10 spacing tolerances.

Lead and Power Screws

HRS manufactures all types of screws, using performance guaranteed materials and offers unique solutions to power transmission problems. All screws are cut from performance guaranteed materials, are subject to stringent quality controls, and are cut rather than rolled resulting in:

Greater accuracy.

A greater precision fit with mating nuts.

The thread is concentric with major diameter.

Superior control of cumulative pitch accuracy.

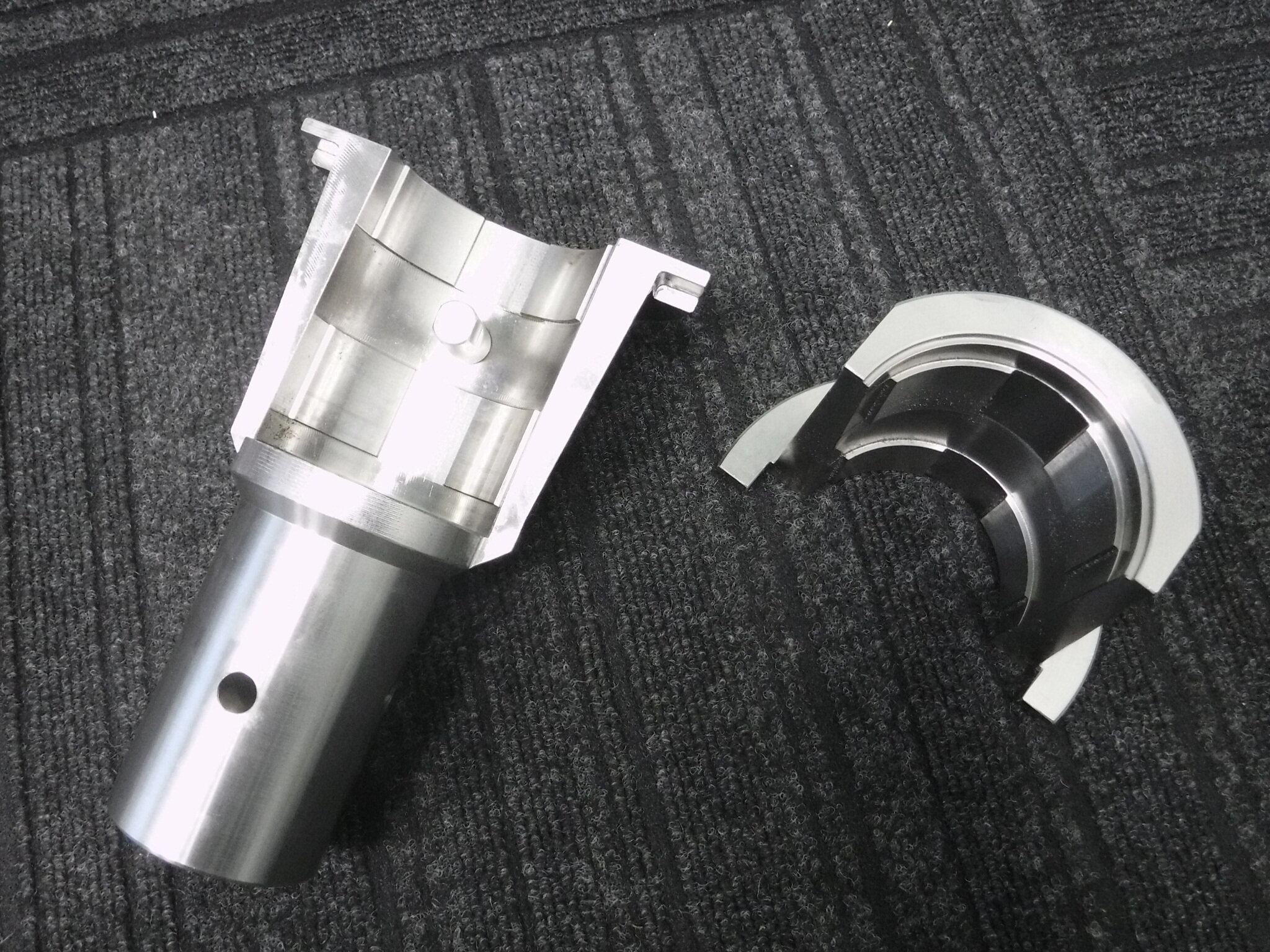

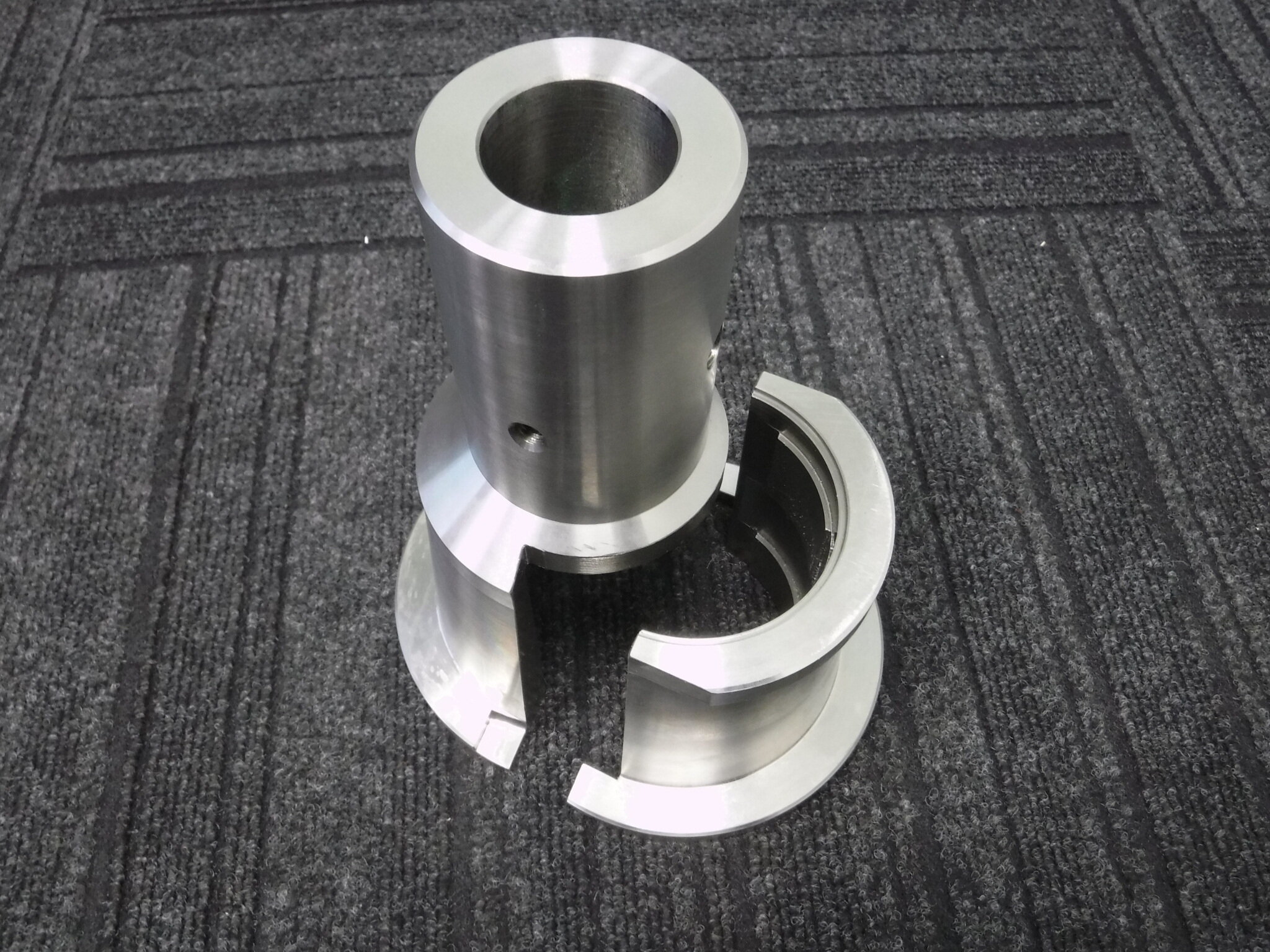

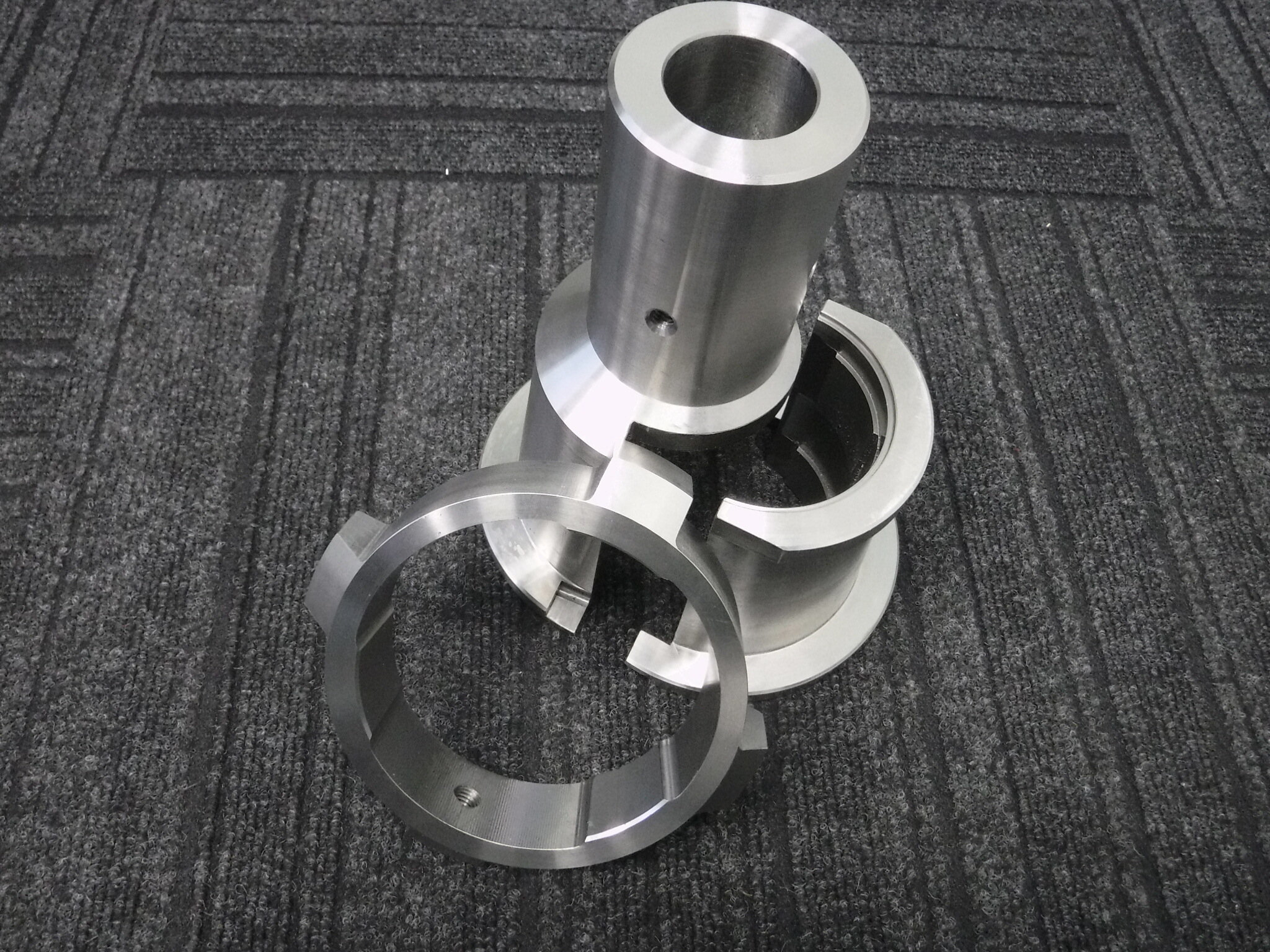

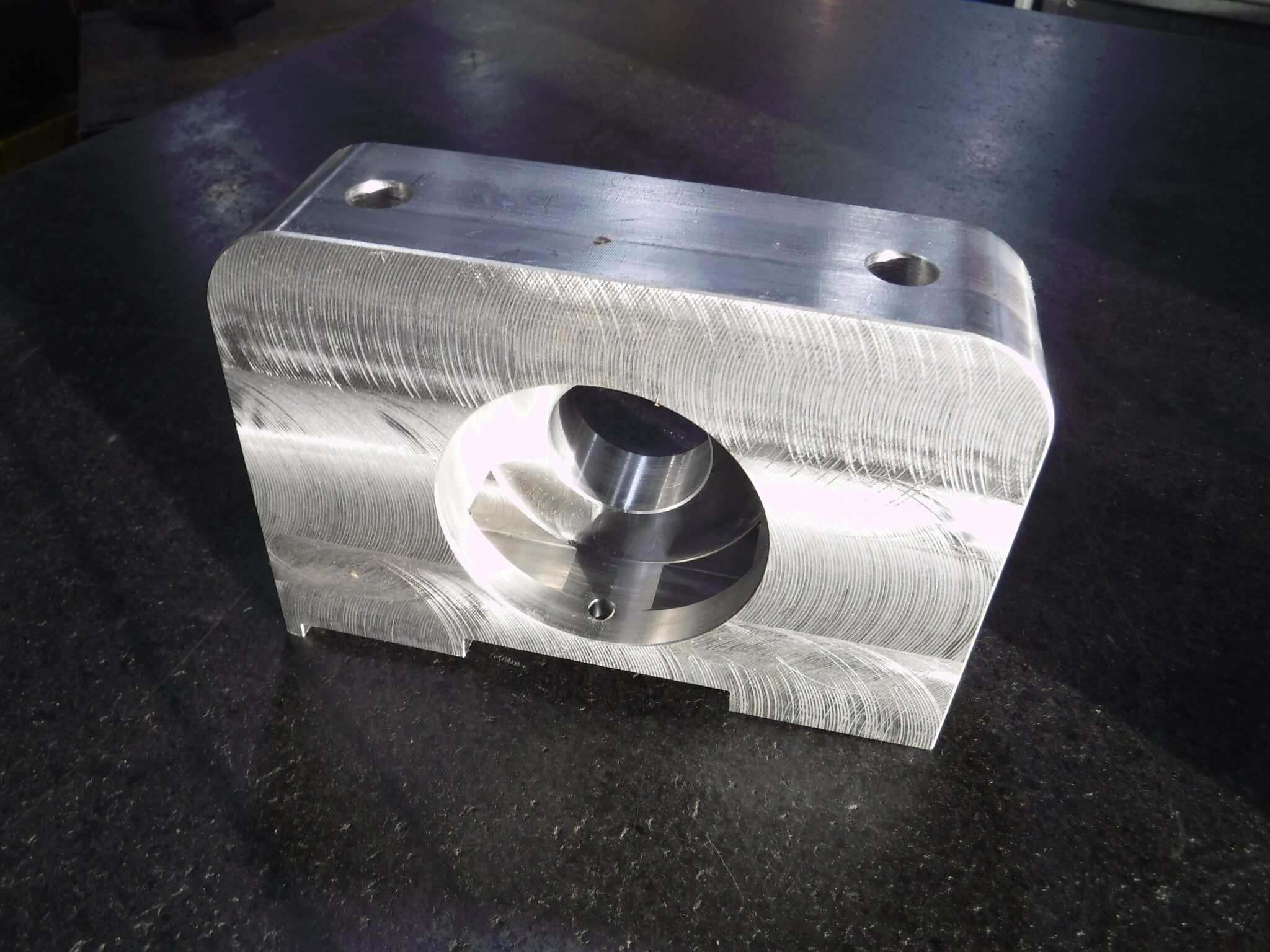

Nuts

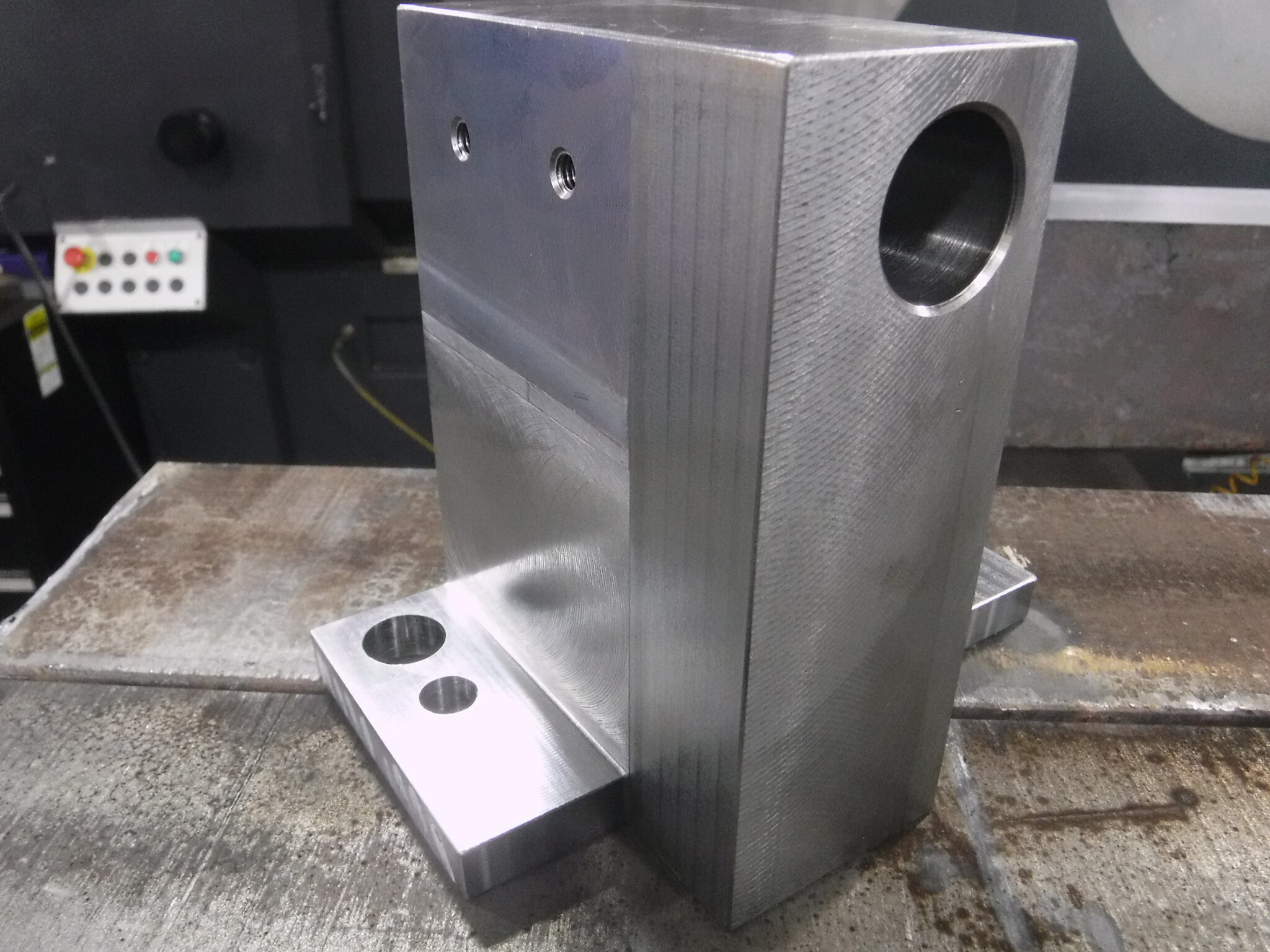

With a wide range of modern CNC machines and a highly skilled workforce HRS can manufacture virtually any nut configuration to exactly match any screw produced working in Steel, Bronze, Plastic or Exotic alloy.

HRS can manufacture high tolerance and safety critical parts where quality and specification compliance is essential.

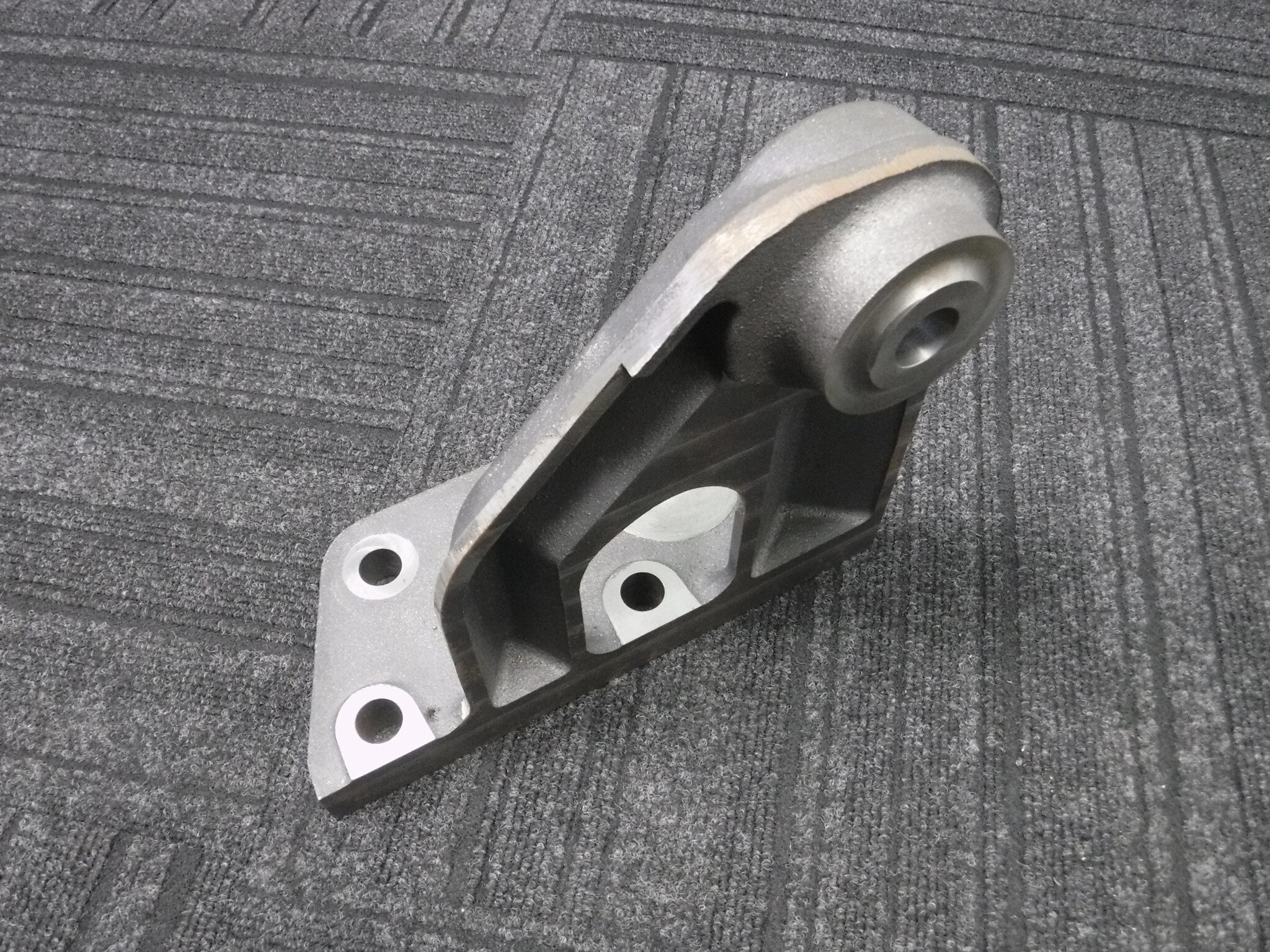

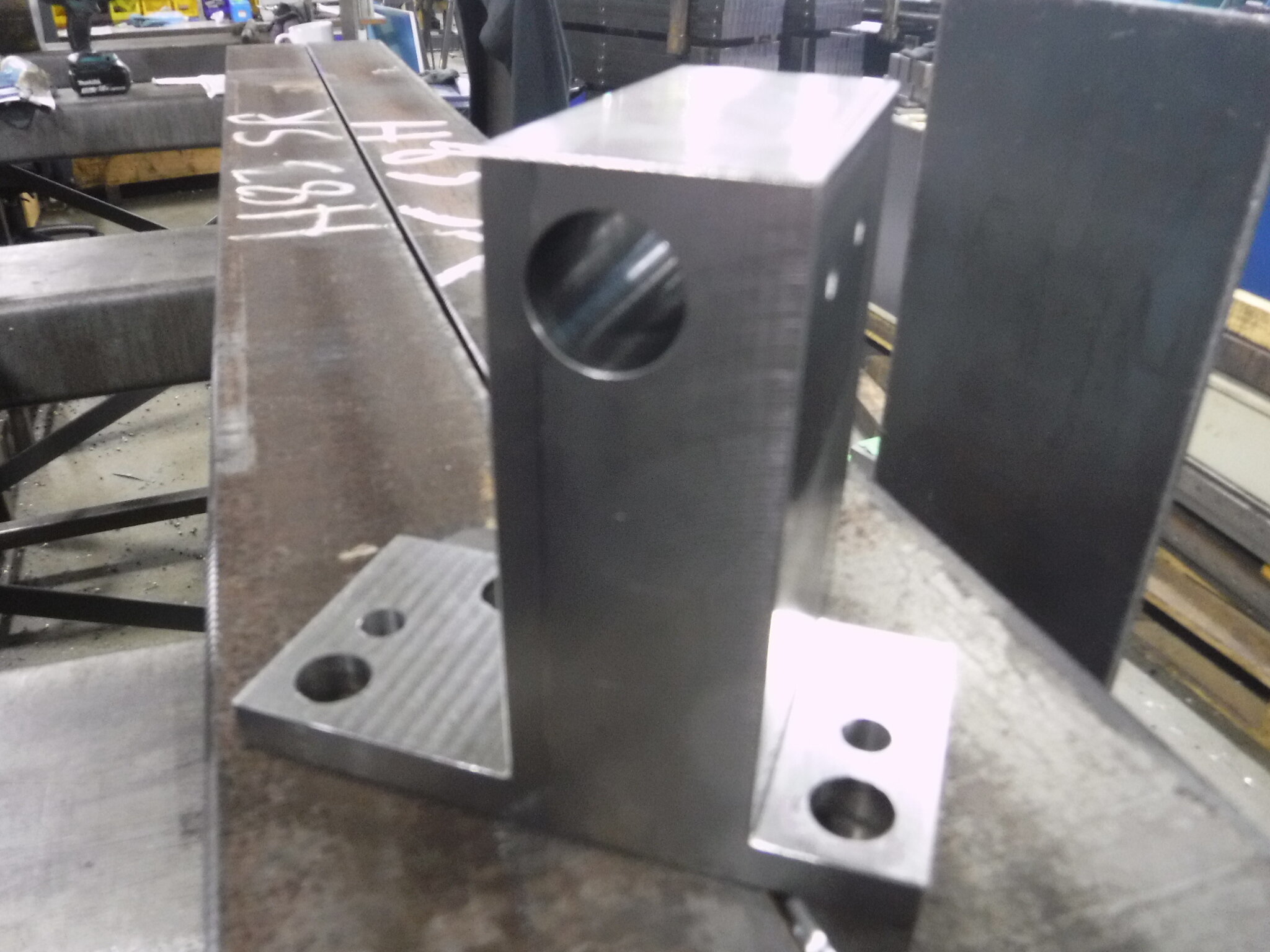

Machined Parts

The installed machine base and the highly skilled work force gives HRS the capability to produce machined parts for customers offering a one-stop shop.

Worms and wormwheels

Safety nut assemblies

Wear strips

Turned parts

Shafts and splines

Machining center parts